Naftosense develops and manufactures addressable hydrocarbon leak detection systems that detect hydrocarbons such as refined gasoline, light and heavy crude oils, lubricants, dielectric oils, solvents, and petrochemical compounds. This blog intends to discuss technologies and products that support industrial leak detection.

Leak Detection Cables for Environmental Protection, Safety, and Profits

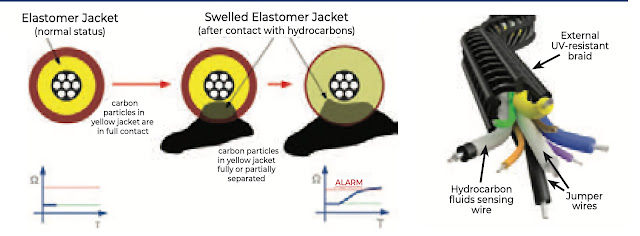

Elastomer Absorption Sensing Cables for Hydrocarbon Leak Detection

Naftosense - The Trusted Source in Hydrocarbon Leak Detection

Why Naftosense is Ideal for Your Application

Naftosense - Simple, Configurable, Outputs with Your Network

Naftosense - Customer Experience

Naftosense - Commitment to Quality

How Naftosense Leak Detection Cables and Sensors Work

Testing

Life Expectancy

Approvals

- Intrinsically safe - Class I, Division 1, Groups A, B, C and D, Class I, Zone 0, AEx ia 11C

- Atex: Intrinsically safe - Il 1 G, Ex ia 11C GbT4

- lECEx: Intrinsically safe - Ex ia IIC GbT4

- Tested by FM Approvals for compliance as per FM Class 3610

New Naftosense Catalog!

The new Naftosense product and solutions catalog.

Hydrocarbon Storage Leak Detection: Gasoline, Jet Fuel, Diesel, and Oil Tanks

Reason to deploy Naftosense Leak Detection for Hydrocarbon Storage Tanks:

- Reports leak volume as the small leak gets larger.

- Zero false alarms.

- Will not react to water.

- High sensitivity.

- Self-calibrating.

- Custom leak detection system design.

- 10–year factory warranty.

Leak Detection for Underground Bulk Storage of Hydrocarbon Products

Secondary Containment with Interstitial Monitoring

Monitors for the Interstitial Space

The Naftosense FLD-TSP7 Control Panel

Features and Benefits of the FLD-TSP7

- Extremely long range of leak detection circuit monitoring

- Easy T-branching – no special devices/components needed

- Adjustable alarm threshold

- Very wide operating temperatures range

- Able to interface with sensor modules for various types of liquids as water, acids, bases, hydrocarbons, alcohols, ketones, etc.

- 10-year warranty

Typical Applications for the FLD-TSP7

- Pipe sections in remote facilities

- Detection of viscous hydrocarbons in substations, pumping stations, etc.

- Detection of leaking fuel from airport hydrant systems, military, and custody transfer installations in harsh outdoor, demanding environmental conditions

- Leak detection in data centers and commercial buildings

Don't Risk Undetected Hydrocarbon Leaks

Leaks of hydrocarbons are a severe problem. The environment and your business are protected when leaks in tank farms, airfields, pipelines, refueling ports, and refineries get discovered early. The key is early identification and pinpointing the leak's source.

The Naftosense Leak Detection System provides you with the following benefits:

- Sensor cables and probes can directly detect and localize the source of a petroleum leak, allowing you to respond quickly before the spill causes harm.

- Fluid leak detection systems for pipelines, tanks, harbors, airports, pumps, and valves that are reliable and accurate.

- Leak detection and location information are far more advanced than that of a standard SCADA system.

- Optional configurations that turn off pumps or valves while not in use.

- Simple or sophisticated systems can be designed for present demands while also allowing future growth thanks to modular and scalable units.

- Local, networked remote alarms and diagnostics, building management system integration, email and SMS notices available.

Naftosense can provide a bespoke leak detection system tailored to your demands, whether your issue is heavy crude oils, lubricants, dielectric oils, solvents, petrochemical compounds, gasoline, jet fuel, diesel, or biofuels. You can detect and locate the source of a leak with the Naftosense leak detection system, allowing you to take decisive action long before the spill gets out of hand. Don't jeopardize your employees' safety, the environment, or your company's reputation on a runaway leak.

Typical Areas Requiring Naftosense Technology:

- Tank farms

- Civilian airfields

- Military airfields

- Pipelines

- Re-fuelling & bunker depots

- Refineries

- Harbors

For more information, contact Naftosense. Call (614) 350-0911 of visit https://naftosense.com.

Naftosense Leak Detection Technology

Polymer Absorption Sensor (PAS) technology is at the heart of Naftosense products (specifically in Naftosense products, Elastomer Absorption Sensors). PAS technology, developed in the 1950s, has a track record of detecting hydrocarbons in extreme conditions and enables real-time, cost-effective critical infrastructure integrity monitoring. We advance this core technology by incorporating innovative acquisition modules, providing limitless options for progressive leak alarms.

Naftosense is one of North America's only leak detection manufacturers willing to customize and configure the ideal solution for each customer. Our innovative, adaptable core technology enables us to accomplish the seemingly impossible while maintaining critical agency approvals. Naftosense can handle any application, no matter how small or large.

Naftosense has the real-world experience to make sense of complex applications by offering an industry-approved, fully functional, long-term leak detection system with data communications and location-based alarms, all backed by a 10-year warranty.

Key Features:- Custom leak detection systems for outdoor environments, hazardous areas, and remote off-line locations

- Zero false alarms–Will not react to water

- High sensitivity, detect heavy oils at low temperatures

- Reduced maintenance–Self-calibrating

- Battery powered options for off-the-grid applications

- 10–year factory warranty

- Can report leak volume as the small leak gets larger

Sensors and Alarms for Leak Detection of Hydrocarbons, Solvents, and Other Liquids

Naftosense

6605 Longshore Street

Suite 240-126

Dublin, OH 43017

Phone: (614) 350-0911

Fax: (614) 350-0914

Email: support@naftosense.com

Welcome to the Naftosense Blog

Polymer Absorption Sensor (PAS) technology is at the heart of Naftosense products (specifically in Naftosense products, Elastomer Absorption Sensors). PAS technology, developed in the 1950s, has a track record of detecting hydrocarbons in extreme conditions and enables real-time, cost-effective critical infrastructure integrity monitoring. Naftosense technology deploys quickly and easily in almost any facility due to its seamless integration with existing infrastructure.

Future posts will focus on applications and deeper insights into the underlying technology. Please check back frequently.