Naftosense designs and manufactures hydrocarbon leak detection systems based on addressable products which detect the presence of hydrocarbons such as refined fuel, light / heavy crude oils, lubricants, dielectric oils, solvents, and petrochemical compounds.

Why Naftosense is Ideal for Your Application

Naftosense Leak Detection systems are susceptible to hydrocarbon liquids and gasses. Some customers have baseline contamination in their facilities that cause other leak detection systems to alarm in “normal” operation. Others have problems during periods of excessive rainfall where hydrocarbons are released from the soil, triggering a false alarm. Naftosense solves ALL micro¬exposure alarm issues by allowing real-time volume reporting and field adjustability of the sensor to calibrate for existing conditions.

In addition, the Acquisition Module will report progressive leak alarms as the volume of the leak increases. Sensors are rugged and built to be immersed in a leak environment and still indicate “increasing leak volume” until the sensor becomes completely saturated at full alarm. After remediation, Naftosense sensors can be re-set and re-installed. Only when the sensor is entirely saturated will you need to use our simple cleaning technique involving common household chemicals. Naftosense sensors are reusable with confidence for ten years or more!

Naftosense - Simple, Configurable, Outputs with Your Network

Communication from the Naftosense system to your PLC, CMS, DCS, and SCADA is simple. You utilize your existing network with your favorite wireless or hard-wired transmitter to easily communicate leak volume and location quickly and efficiently. The absence of complicated 3rd party panels and proprietary communication protocol allows a seamless, inexpensive installation with standard equipment as the backbone of your new leak detection system.

Naftosense - Customer Experience

Naftosense supports customers through knowledgeable and dedicated sales and support staff that can assist in selecting the proper leak detection system and matching ideal solutions with existing communications requirements. In addition, we maintain an extensive supply of product inventory on hand to quickly fulfill orders and reduce lead times. Our sales and support staff are readily available and accessible, so customers rapidly get the support they need.

Naftosense - Commitment to Quality

At Naftosense, quality means performance. Each product passes tests multiple times before getting a Naftosense label. With Production processes that strive for continuous improvement and exhaustive performance testing, we are confident that our products meet and exceed all applicable standards before they ever leave our facility. Naftosense puts a 10-year factory warranty on all products to prove our commitment to the highest installation standards.

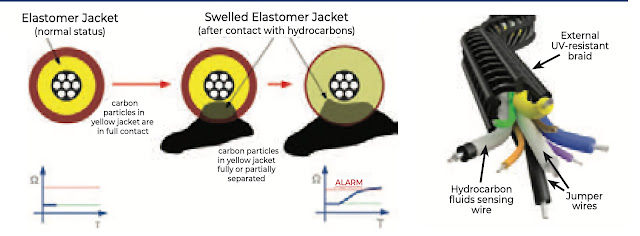

How Naftosense Leak Detection Cables and Sensors Work

Naftosense leak detection technology uses Polymer Absorption Sensor (PAS) technology. PAS technology was developed in the 1950s and had a proven track record of detecting hydrocarbons in extreme conditions and enables real-time, cost-effective critical infrastructure integrity monitoring. Naftosense can dictate leak volume and decipher old and new material in coordination without patented controller technology.

Testing

Naftosense leak detection systems are tested to the most stringent industry standards to ensure maximum reliability and performance for our customers.

Life Expectancy

Our extensive scientific testing and field history proves that Naftosense leak detection cables will perform for many decades when properly installed and maintained. An industry-leading ten-year warranty is standard with all products sold.

Approvals

- Intrinsically safe - Class I, Division 1, Groups A, B, C and D, Class I, Zone 0, AEx ia 11C

- Atex: Intrinsically safe - Il 1 G, Ex ia 11C GbT4

- lECEx: Intrinsically safe - Ex ia IIC GbT4

- Tested by FM Approvals for compliance as per FM Class 3610

(614) 350-0911