In today's world, where environmental protection and safety are paramount concerns, businesses involved in handling petroleum fuels face increasingly stringent regulations. Leaks from pipelines, storage tanks, and refueling areas can devastate the environment and a company's reputation. Enter Naftosense fuel leak detection systems, offering reliable and accurate solutions to detect and pinpoint the source of leaks before they become catastrophic.

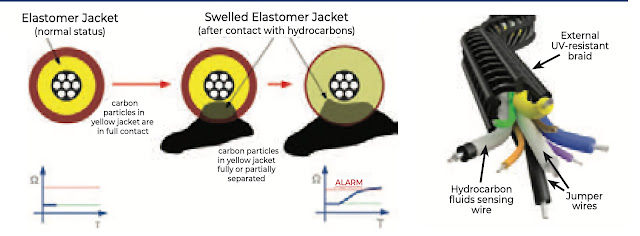

Naftosense is at the forefront of leak detection technology, with sensor cables installed worldwide. The heart of the system lies in the sensor cables and probes that can directly detect the presence of hydrocarbons. These sensors come in various forms, including cables for double containment pipe systems, indoor day tanks, pumps, and valve pads and cables for detecting liquid fuels in sumps or containment areas. The sensor cables and probes connect to various monitoring and alarm panels, from simple battery-powered LED flashers to sophisticated network master control systems.

Naftosense fuel leak detection systems are used in various sectors of the oil and gas industry. In high-consequence areas where pipeline leaks can have severe impacts, Naftosense's hydrocarbon sensing cables serve as effective mitigating devices. These systems offer a cost-effective alternative to SCADA for batch and transfer lines, providing better sensitivity and actionable alarms.

In airport systems, Naftosense cables and probes offer continuous leak detection and precise location, allowing for quick response and minimizing disruption to operations. Tank farms also benefit from these systems, with cables installed around the circumference or beneath tank floor plates to safeguard against leakage through corroded bottom plates.

Above-ground piping at terminals, refineries, harbors, and oil fields can be monitored by strapping sensor cables to the bottom of the pipes. These cables detect the first drips of fuel or oil, enabling swift action to prevent further spillage.

Naftosense fuel leak detection systems provide a comprehensive solution to the challenges businesses face with petroleum fuels. By offering reliable, accurate, and customizable leak detection and location capabilities, these systems help protect the environment, ensure safety, and safeguard the reputation of the companies that employ them. As regulations continue to tighten and the demand for environmental responsibility grows, Naftosense stands ready to assist businesses in meeting these challenges head-on.

(614) 350-0911